The Official UK Parker Polyflex® Supplier

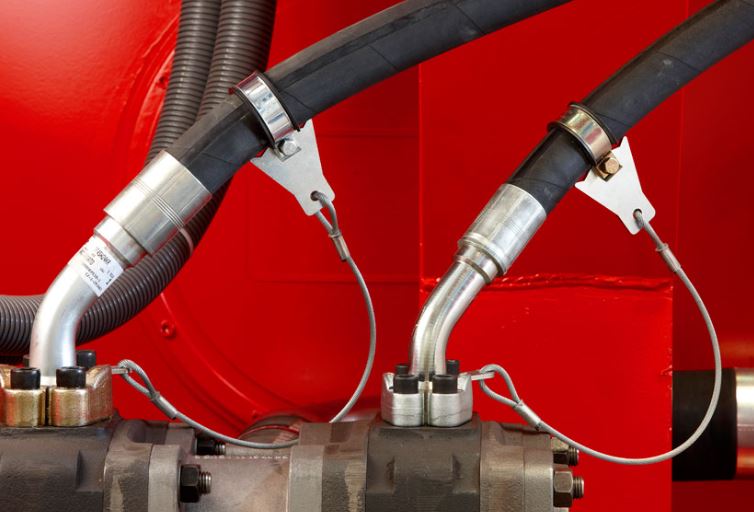

Stopflex Hose Retention System

The energy contained within a pressure hose, in case of disconnection from the fitting, can be very dangerous to anyone or anything in its vicinity. The Stopflex retention system was designed to arrest the trajectory of the flexible hose, thus avoiding that the energy contained inside may trigger a frightening “whip effect”. As a matter of fact, thanks to the Stopflex system, the hose is secured to the plant by means of a cable protecting both the operators and components.

Stopflex components can be applied to all kinds of flexible hoses. A band, equipped with a rubber gasket, remains perfectly secured, simultaneously allowing the hose to swell according to the working pressure. The retaining components can be secured to nipples, to SAE flanges or other system components.

The Stopflex system, upon correct mounting, was manufactured and tested to ensure the retention of the hose up to the maximum pressure indicated in this catalogue in compliance with the following standards regulating the manufacture of hydraulic flexible hoses: EN 853 EN 854 EN 855 EN 856 EN 857 SAE J517

Stopflex components can be applied to all kinds of flexible hoses. A band, equipped with a rubber gasket, remains perfectly secured, simultaneously allowing the hose to swell according to the working pressure. The retaining components can be secured to nipples, to SAE flanges or other system components.

The Stopflex system, upon correct mounting, was manufactured and tested to ensure the retention of the hose up to the maximum pressure indicated in this catalogue in compliance with the following standards regulating the manufacture of hydraulic flexible hoses: EN 853 EN 854 EN 855 EN 856 EN 857 SAE J517

How the system works...

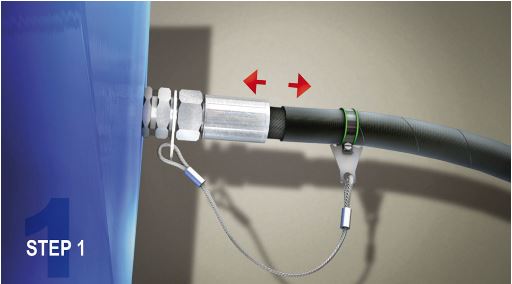

1. Disengagement

|

The Stopflex system does not operate during the step of disengaging the flexible hose, but, if applied correctly, it ensures that the hose is fully disengaged from the ferrule that restrains it. During this step, the flexible hose gains velocity and power due to the pressure increase of the oil contained therein.

|

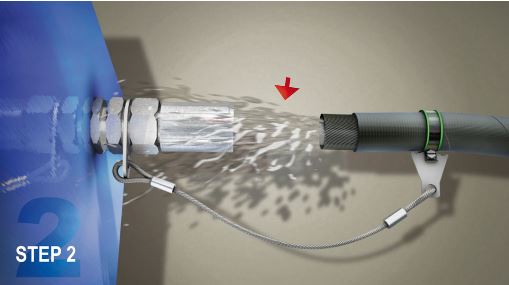

2. Release/Venting of Pressure

|

During this step, the pressurised oil exits from the flexible hose. The hose begins to release the energy contained therein, and gains considerable velocity, triggering a hazardous “whip effect” which is very dangerous to anyone or anything in its vicinity.

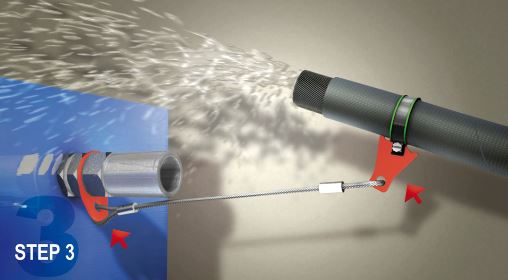

3. Restraint |

Once the hose has been disengaged and the pressure released, the flexible hose can be restrained. This is where the Stopflex system gets into operation: the stainless steel cable is tensioned and deformed while the plate cuts into the rubber of the hose, preventing the clamp, firmly attached to the hose, from disengaging. The hose clamp and plate start to deform in turn, elastically absorbing the force released from the travel of the flexible hose.

This is a critical step which occurs within just a few seconds in which the materials and the components of the system, previously sized and tested, stop the dangerous travel of the flexible hose. |